Programmable Logic Controller (PLC) Design Build Services

The Gas Life Safety System needs a control system to provide warnings, shutdowns, and summon help as needed. There are options for small and limited systems, but most systems use a Programmable Logic Controller or PLC to provide functionality. The PLC is robust technology that can be programmed to provide any number of control sequences for annunciation, shutdown, display, and offsite notification. The advantage of using this technology is that it can be readily expanded and grow as needs dictate.

MDC specializes in PLC control systems for Gas Life Safety. Our experience will guide you through the technical challenges associated with equipment choice, interconnection, integration with other equipment, programming, testing, and all the way through final acceptance. Engaging us early on will provide you with a wealth of experience and the knowledge that your system will be professionally designed and effective.

MDC Systems’ approach to design begins with an analysis of the client’s current and future operational requirements. This ensures the design addresses both the facility’s safety needs for day one implementation as well as for future needs. A complete design and implementation would typically include:

- Hazard Analysis: This can be a simple review of the site, and the hazards present or a more formal approach such as a Process Hazard Analysis (PHA). The purpose of a review is to establish what equipment is needed for the application. The review will also consider how the system should be programmed.

- Design: Once the system scope is defined, MDC’s design team will start the design. During this phase we consider code requirements and system architecture. We figure out the best equipment and architecture for your current application with future expansion and integration in mind.

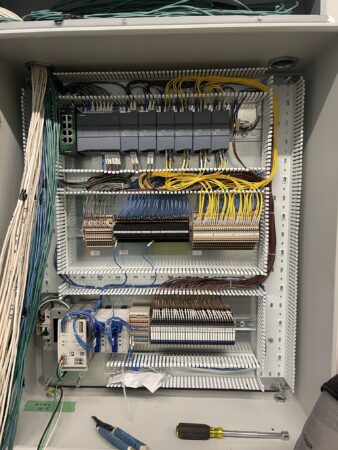

- Drawings: A drawing set is prepared that includes all the equipment and detail necessary to build the system. You will be able to review and comment on the system design. We incorporate any comments prior to building the system control panel. The MDC PLC panel includes these key features for usability.

- Panel Build: MDC builds its own panels to assure quality and reliable service. We use high quality methods and material throughout. All components are recognized as suitable for use in critical applications.

- Features: The following features are available when you use an MDC designed control panel.

- UL Listing: Since the 2005 edition, the National Electrical Code has required that all industrial control panels be listed by a Nationally Recognized Testing Laboratory. The UL Listing meets this requirement and assures that the panel is designed, built, and labeled in compliance with the standard ANSI / UL508A. This listing is traceable, look for the UL Label.

- Intuitive Software: The user interface is either a touchscreen (HMI) or computer system (SCADA). The software that the user sees is easy to understand and use. Simplicity is especially important during an emergency.

- Silence for Audibles: The audible devices can be silenced during an emergency while leaving the strobe lights on. This feature allows for effective radio and phone conversations during an alarm without the background noise from the horns.

- User Adjustable Alarm Setpoints: MDC systems allow the user to adjust the alarm setpoints for each gas detector. Setpoints need to be adjusted from time to time. Without this feature, a service call would be needed to change a setpoint.

- Bypass for Inputs: Our systems allow the user to bypass points while servicing the system. This feature prevents unwanted alarms. This is password protected, so that it can’t be accidently activated.

The choice of a control system is an important consideration. It will be one that will last for many years. It should be dependable throughout its life and be able to be expanded when growth is called for. The MDC control panel meets this mandate.